Powder Flow Testing Workstation PTW

The Powder Testing Workstation PTW has been specifically designed to address the specifications in and comments raised by the European Pharmacopoeia Chapter 2.9.36 and US Pharmacopoeia Chapter <1174> on Powder Flow. The PTW Tester provides a range of options for testing pharmaceutical powders including three of the four methods quoted in the pharmacopoeia in a single, cost effective unit.

- Flow through an orifice

- Angle of Repose

- Shear Cell

In addition to providing the test methods detailed in the harmonized pharmacopoeia chapters, it is also suitable for flowability testing according to Ph.Eur. 2.9.16.

An optional balance/timer simplifies time vs mass testing.

Powder flow depends on several factors, some of which relate to the powder material and some to the actual manufacturing processes, its ability, for example, to flow from a container (hopper, funnel, cylinder, etc.) or its compressibility in forming a tablet. The Pharmacopoeias recommend three methods for testing powder flow:

- Flow through an orifice

- Angle of Repose

- Shear Cell

Flow Through an Orifice (Cylinder Attachment)

Measuring the ability and the time taken for a powder to flow through an orifice of known size is a useful method of quantifying powder flow.

At the same time, it is important to recognise that the ability of the powder to flow through the orifice can be affected by factors other than the characteristics of the powder itself.

Such factors include the shape and material employed in the construction of the powder container, the diameter and height of the powder bed and the shape of the orifice concerned.

The Pharmacopoeia suggest that the use of a circular cylinder as the powder container encourages powder over powder flow as opposed to powder over container wall, minimising any effect brought about by differences in the material used to produce the powder container. As the title suggests, this technique is only suitable for materials that flow – not cohesive materials. Assuming this to be the case, then the Pharmacopoeia suggests that providing:

- The height of the powder bed (the ‘head’) is much greater than that of the orifice

- The diameter of the opening is greater than 6 times the diameter of the particles

- The diameter of the cylinder is greater than 2 times the diameter of the opening then any difference in results brought about by either powder bed or orifice can be considered negligible. The cylinder attachment has been designed to take all of these factors into account.

| The cylinder attachment comprises a stainless-steel cylinder measuring 76 mm x 57 mm and a capacity of 200 mL, each module comes complete with 20 interchangeable stainless-steel disks with a precision orifice from 4 to 36 mm. The attachment comes complete with a set of 20 interchangeable stainless steel discs each containing a precision drilled hole in the centre covering the following sizes: 4, 5, 6, 7, 8, 9, 10, 12, 14, 16, 18, 20,22, 24, 26, 28, 30, 32, 34 and 36 mm. A shutter covers the hole during filling. This can be smoothly removed without vibration to allow the powder to flow through the selected hole. The cylinder attachment can be used in two ways:

The addition of our Balance/Timer Attachment to the shutter mechanism simplifies Mass vs Time tests. |

Pharmacopoeia Compliance: | Ph. Eur. 2.9.36 and 2.9.16 USP <1174> |

| Catalogue Number 1670: | Powder Testing Workstation PTW Stand incl. Baseplate & Upright with Shutter Module |

Catalogue Number 1671: | Cylinder Attachment incl. stainless-steel cylinder size 200mL, Plastic Powder Funnel, set of 20 stainless steel discs, 1000mL Beaker, Disc & Cylinder Rack |

| Optional Accessories: | |

| Catalogue Number 1678: | Timer Attachment |

Catalogue Numbers: 1673 | Balance options: Kern Balance – 1. D.P 10000g Max Kern Balance – 2 D.P 400g Max Ohaus Balance – 3 D. P 440g Max |

Flow Through an Orifice (Funnel Attachment)

In certain instances where, for example, the purpose of the test is to simulate flow in a hopper or other production situation, it may be preferable to use a funnel in the form of a truncated cone.

| The funnel attachment is based on the stainless steel flow funnel and nozzle described in the USP <1174> and Ph. Eur. Chapters 2.9.36 and 2.9.16 for Flowability. It has a capacity of approx. 400ml. The attachment is supplied with three nozzles corresponding to aperture sizes of 5, 7, 10, 15 and 25 mm respectively. Both funnel and nozzles are manufactured from Pharmaceutical grade 316 stainless steel. The nozzles can be quickly interchanged using the connecting nut provided for that purpose. The opening at the bottom of the funnel is secured by means of an adjustable shutter which is closed during the filling operation. The test is carried out in a similar manner to that of Method A (Mass vs Time) of the cylinder attachment. The addition of our Balance/Timer Attachment to the shutter mechanism simplifies Mass vs Time tests. |

Pharmacopoeia Compliance: | Ph. Eur. 2.9.36 and 2.9.16 USP <1174> |

| Catalogue Number 1670: | Powder Testing Workstation PTW Stand incl. Baseplate & Upright with Shutter Module |

| Catalogue Number 1672: | Funnel Attachment incl. Stainless Steel Funnel, Funnel Adaptor, Nozzle Set (5, 7, 10, 15 and 25 mm), Nozzle & Funnel Rack, 1L Beaker |

| Optional Accessories: | |

| Catalogue Number 1678: | Timer Attachment |

Catalogue Numbers: 1673 | Balance options: Kern Balance – 1. D.P 10000g Max Kern Balance – 2 D.P 400g Max Ohaus Balance – 3 D. P 440g Max |

Balance and Timer Attachments

By adding a balance and a timer linked to a micro-switch located on the shutter mechanism, it is now possible to conduct time vs mass tests using either cylinder or funnel methods without the need for an external stopwatch.

The balance/timer option allows the use of the unit in 4 modes:

- Determination of the flow time of a predetermined sample weight

- Determination of the flow time of a predetermined sample volume

- Determination of the weight of sample in a predetermine time

- Plot of time against sample weight (weight/time)

| PTW with Cylinder and Balance Attachments | PTW with Funnel and Timer Attachments |

|  |

| Catalogue Number 1678: | Timer Attachment |

Catalogue Numbers: 1673 | Balance options: Kern Balance – 1. D.P 10000g Max Kern Balance – 2 D.P 400g Max Ohaus Balance – 3 D. P 440g Max |

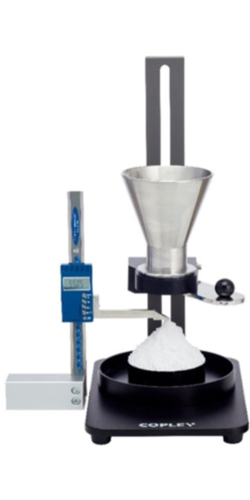

Angle of Repose Attachment

The angle of repose is the angle (relative to the horizontal base) of the conical pile produced when a granular material is poured onto a horizontal surface. It is related to the density, surface area and coefficient of friction of the material concerned.

| The angle of repose attachment comprises a 100 mm diameter circular test platform together with a digital height gauge. Powder heights of up to 145 mm can be easily read from the clear display. The test platform has a protruding outer lip in order to retain a layer of powder upon which the cone is formed. Surplus powder is collected in a tray below the test platform. For this particular test, the funnel is normally equipped with a special nozzle mounted above the test platform. If necessary, the contents may be stirred to assist in the powder flow. The tangent of the angle of repose (in degrees) can be determined by reading off the height of the powder cone in mm from the digital display of the height gauge and dividing it by 50. |

Pharmacopoeia Compliance:

| Ph. Eur. 2.9.36 and 2.9.16 USP <1174> |

| Catalogue Number 1670: | Powder Testing Workstation PTW Stand incl. Baseplate & Upright with Shutter Module |

Catalogue Number: 1674 | Angle of Repose Attachment incl. digital height gauge, Stainless Steel Funnel, AoR 10mm nozzle, Funnel Adaptor, Powder Retaining Tray & 100mm Base |

| Optional Accessories: | |

| Catalogue Number 1676: | Stirrer Attachment for PTW |

Catalogue Numbers: 1673 | Balance options: Kern Balance – 1. D.P 10000g Max Kern Balance – 2 D.P 400g Max Ohaus Balance – 3 D. P 440g Max |

Shear Cell Attachment

Shear cell methodology is widely used in the pharmaceutical industry to determine the flow properties of fine grained powders and bulk solids and how they will behave in bins, hoppers, feeders and other handling equipment. The ability of a material to flow through such devices is dependent on the bulk density of the material and its shear strength.

| The Shear Cell Module for PTW measures the force required to shear a circular disc through a prepared sample of bulk material. |

| Catalogue Number 1670: | Powder Testing Workstation PTW Stand incl. Baseplate & Upright with Shutter Module |

| Catalogue Number 1675: | Shear Cell Attachment incl. 5 kg Flat Cast Iron Mass, Stainless Steel Funnel, Funnel Adaptor, 25 mm Nozzle, Shear Cell Base, Test Chamber, Loading Vessel |

Powder Testing Assistant™ PTA 100i

The Powder Testing Assistant PTA 100i is an all-in-one solution designed to optimise powder test methods. Combined with the Powder Testing Workstation™ PTW, it guides users through each test method, ensuring precision and consistency at every step. Featuring an integrated timer, real-time weight capture from a connected balance, and versatile reporting options, the PTA 100i streamlines workflows, minimises user errors and enhances data integrity, making it the ultimate tool for reliable powder testing across diverse applications.

PTA capabilities are now also available on the JVi Series of Tapped Density testers.

| Pharmacopoeia Compliance: | USP, Ph. Eur., ASTM and ISO standards |

| Catalogue Number 1680: | Powder Testing Assistant™ PTA 100i |

Compatible with:

| All six Powder Testing Workstation PTW testing methods:

|

Click here to view the brochure: Powders Testing

Newsletter Signup

Sign up to our newsletter for the most up-to-date development of products, industry news, special offers and much more!

Location: IRELAND

Unit 21, Waterford Business Park,

Cork Road, Waterford

Ireland, X91 P224

E-mail:

Contact: UK

Tel: +44 (0)20 346 898 13

E-mail: info@antechsolutions.co.uk

Web: www.antechsolutions.co.uk